|

Feininger(Nanjing) Energy Saving Technology Co.,Ltd

|

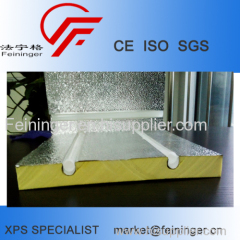

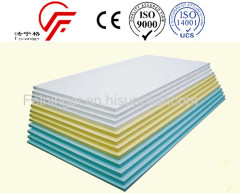

fireproof insulation CO2 XPS Foam board|extruded polystyrene insulation board

| Price: | 80.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

XPS foam board is an extruded polystyrene insulation manufactured through a plastic extrusion process.

Product Description

XPS foam board is a kind of light weight rigid panel, its main raw materials is GPPS. Its cell structure is closed, continuous and alveolate, every cell wall is interlinked and consistent. This kind special structure makes the product have very good heat resistance, high humidity resistance, low water absorption, very good sound insulation, high compressive strength, creep resistance and good dimensional stability. The property of XPS foam board is stably and it is very light, easy to transport and cut. It is the best heat resistant materials in the world.

1. Brief Introduction

XPS Foam Board is Extruded Polystyrene Insulation Foam, which is made from Polystyrene Granule, together with Talcum Powder, Color Masterbatch, and HCFC. All these materials are heated, blended, plasticized and extruded out into the shape of rigid XPS Foam Board panel. XPS Foam Board has perfect closed-cell structure which enables such foam has the excellent property of low water absorption, low heat-conductivity, high compressive stress and anti-aging.

2. XPS Properties

a. excellent heat-insulation property.

The structure of 99% closed-cell pores ensures long and stable performance of heat-insulation. It has been the prevailing heat-insulation building material.

b. high compressive stress

The special closed-cell structure enables XPS Foam board has compressive stress from 150Kpa to 500Kpa and can withstand pressure of all kinds of floors. Hence, it is widely used in highway basement, airport track, square floor, huge refrigerating system and domestic decoration.

c. great Water-resistance

The special structure guarantees the molecule stability and no clearance between molecules, which solve the problem of leaking, penetrating, condensation and frosting.

d. light weight

Thoroughly foamed pores and cell structure makes XPS Foam Board light-weight, easy to cut, convenient to install.

e. Stability, Anti-corrosion

Anti-aging and anti-decomposing property makes XPS Foam Board stay excellent performance, even under high temperature. It is recorded that XPS Foam Board will stay its function and does not volatilize any toxicity within 3 to 4 decades.

f. Environment Friendly

XPS raw materials are environment friendly and the production process does not cause any pollution. Also the scraps or powders incurred during installation process can be recycled into granule which is feasible to be re-used.

Technical Data Executive Standard: GB/T 10801.1-2002 | ||||||||||||

Item |

Unit | Property Index | ||||||||||

With Skins | Without Skins | |||||||||||

X150 | X200 | X250 | X300 | X350 | X400 | X450 | X500 | W200 | W300 | |||

Compressive Strength | KPA | ≥150 | ≥200 | ≥250 | ≥300 | ≥350 | ≥400 | ≥450 | ≥500 | ≥200 | ≥300 | |

Water Absorption, dipped in water for 96h | %(by volume) | ≤1.5 | ≤1.0 | ≤2.0 | ≤1.5 | |||||||

MoisturePermeability, 23°C±1°C,RH 50%±5% | Ng/(m.s.Pa) | ≤3.5 | ≤3.0 | ≤2.0 | ≤3.5 | ≤3.0 | ||||||

Heat Insulation | Heat Resistance Thickness25mm 10°C 25°C |

(m2·K)/W |

≥0.89 ≥0.83 |

≥0.93 ≥0.86 |

≥0.86 ≥0.86 |

≥0.86 ≥0.86 | ||||||

Heat Conductivity Average Temp. 10°C 25°C |

W/(m·K) |

≤0.028 ≤0.030 |

≤0.027 ≤0.029 |

≤0.030 ≤0.032 |

≤0.030 ≤0.032 | |||||||

Dimensional Stability 70°C±2°C, 48h | % | ≤2.0 | ≤1.5 | ≤1.0 | ≤2.0 | ≤1.5 | ||||||

Packing information:

XPS (Rigid Extruded Polystyrene Foam Board) | |||

Transparent Plastic Bag for Packing | 40'HQ | 40'GP | 20'GP |

50mm-600mm-1200mm | 10pcs/package 0.036m3/pc 0.36m3/package | ||

180packages | 138packages | 55packages | |

64.8m3 | 49.68m3 | 19.8m3 | |

1800pcs | 1380pcs | 550pcs | |

In bulk | In bulk | In bulk | |

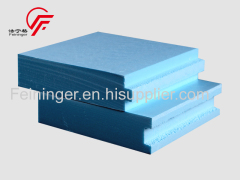

Common Specification for XPS Board

20*600*2400mm 25*600*2400mm 30*600*2400mm

40*600*2400mm 45*600*2400mm 50*600*2400mm

75*600*2400mm 80*600*2400mm 100*600*2400mm Also we can make board as wide as 1200mm. For special dimension, please contact us for detailed information.