|

Feininger(Nanjing) Energy Saving Technology Co.,Ltd

|

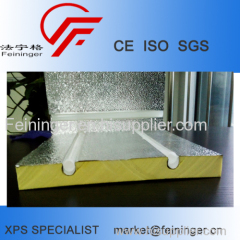

Underfloor Heating System Insulation Panel|extruded polystyrene Aluminum foil

| Price: | 80.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

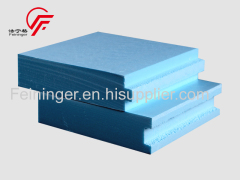

XPS foam board is an extruded polystyrene insulation manufactured through a plastic extrusion process.

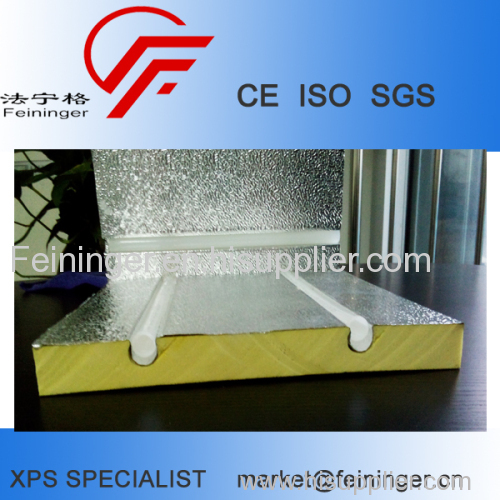

XPS insulated floor panel, Aluminum foil composite underfloor heating systems, underfloor heating mat :

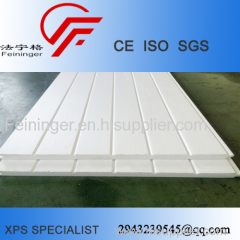

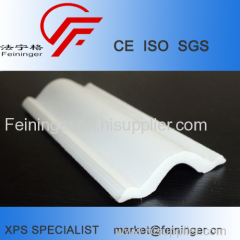

Underfloor Heating System Panel which has a return side to other side is an efficient thermal insulation material in underfloor heating system.

The hot pipes can be installed into the grooves, if the XPS board is covered by aluminum foil or aluminum panel, the energy could be spreaded efficiently and evenly.

Feininger XPS Foam Board:

1.Stable performance and anti-aging: The extruded polystyrene (XPS) insulation boards can be used 35-50 years.

2.Resistance to compression: compared with other thermal insulation material(200Kpa for EPS), it has better compressive strength(around 300Kpa), which make it the ideal solution for heavy domestic or industrial loads

3.Water resistance: Polyfoam is almost 100% closed cell and as such is unaffected by moisture

4.Lightweight: volume optimization and easy to handle

5.Resistance to deformation

6.Resistance to impact

7.Versatile: the closed cell structure and density of Polyfoam allow specific edge details and surface finishes to be cut into the boards to make them as fit for the job as possible. Moreover, Polyfoam can be cut into almost any shape

100% ozone friendly

8.Recyclable: Polyfoam can be 100% recycled

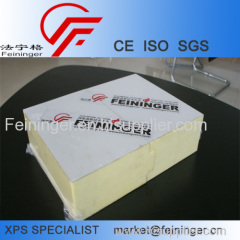

9.XPS Insulation Board Production Process: Polystyrene Granule, Talcum Powder, Master batch, Blowing Agent are mixed and melted in Extruder. The melt material will be extruded out of Slot Die, then through Calibrator, we reach a panel shape. After cooling, cutting, edge trimming, we will pack in water-proof plastic bag. This is the XPS Foam Board in market.

10.Properties:Heat Insulation, Water-proof, Noise-elimination, Anti-corrosion, Anti-aging, Light-weight, High Compressive Strength and Low Moisture permeability.

11.Application: Wall Insulation, Inverted Roof Insulation, Floor Insulation, Sanwich Panel, Steel Plate Sandwich Panel, PVC Sandwich Panel, Cold Storage Insulation, Refrigeratory, Airport Ground, High speed Rail-way Base.

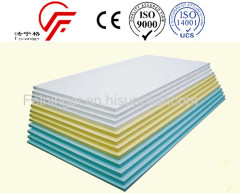

12.Specification: Thickness: 20-120mm Width: 600mm, 900mm, 1200mm Length:1200mm, 2400mm, 3000mm or your option Color: light-yellow, blue, green, pink Loading: 65 M3/40'HQ

Our Services

Manufacture brand-new XPS Foam Insulation Board.

Carry out on-line quality supervision and test the insulation material before shipping.

Pack XPS Foam in plastic bag.

Issue Test Report.

Ship the material by full container load.

Make arrangement of transportation.

Instruct how the XPS Sandwich Panel is applied.

certificates: